Why does 1stVision focus (no pun intended) so much on machine vision lenses. As the old saying goes, if you have garbage in, you get garbage out.

Why does 1stVision focus (no pun intended) so much on machine vision lenses. As the old saying goes, if you have garbage in, you get garbage out.

The lens is the input to the machine vision system. A low quality lens means that you have already degraded the image coming into the sensor. For instance, let’s say you chose a camera with 5um pixels, which equates to a lens being able to resolve 100 lp/mm. If your lens’ Modular Transform Function (MTF) is only 50 lp/mm, you should have chosen a camera with 10um pixel size, because the lens can’t do any better than that. As a note, don’t infer that a camera with 10um pixels is worse than a camera with 5umpixels from this example, as that is not true. Learn more on MTF here

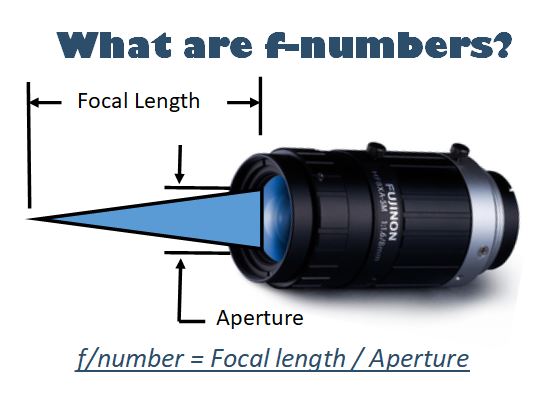

A machine vision lens gathers light and then focuses it. When we talk about focus, we are talking about the MTF, but when we discuss light gathering properties, we need to discuss the lens f-number.

A machine vision lens gathers light and then focuses it. When we talk about focus, we are talking about the MTF, but when we discuss light gathering properties, we need to discuss the lens f-number.

The f-number is defined as the ratio of the focal length by the aperture width (diameter of the entrance pupil). So a 50mm focal length lens with a f-number of 2 has a 25mm entrance pupil. The lower the f-number, the more light will be allowed into the system, however this equates to more expensive lens as you need more glass to make a wider entrance pupil.

f-stop

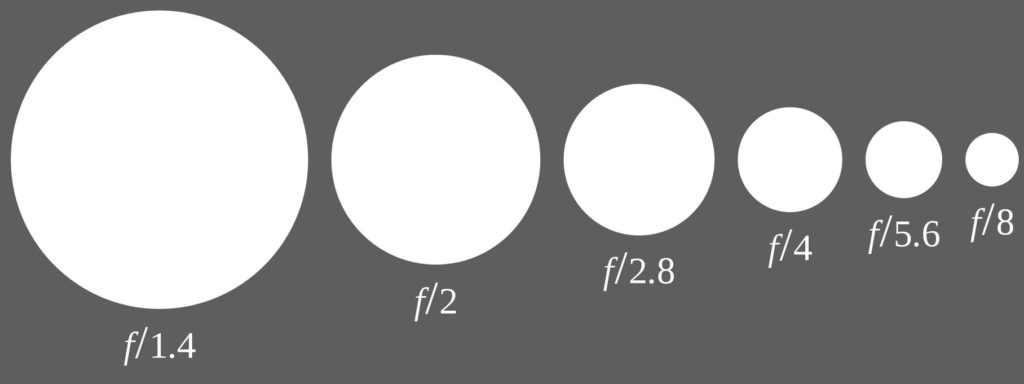

Many camera lenses have an adjustable iris that opens and closes at the front of the lens to limit the amount of light coming in. When open all the way, the f-stop is the f-number. From there, each f-stop from wide open halves the amount of light, which corresponds to reducing the size of the aperture by 1/sqrt(2) or about 0.707 and in turn halving the area.

The f-stop is represented by a sequence of these numbers below, each letting in half the light.

Sequence: f/1, f/1.4, f/2, f/2.8, f/4, f/5.6, f/8, f/11, f/16, f/22, f/32, f/45, f/64, f/90, f/128

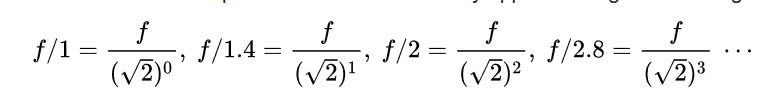

The sequence is obtained by approximating the geometric sequence

Characteristics of the f-stop

- Most lenses are designed to be optimal in the F4-F5.6 range, in which they have the best MTF.

- The higher f-number (ie f/8 ) is, or the more closed the aperture is, better the depth of field if achieved

- The lower the f-number (ie f/1.4) is, or the aperature being wide open is where you get the least depth of field, but not great MTF.

In a practical application, you need to trade off exposure time, depth of field, and available machine vision lighting. These three variables are always in tension. If you need fast exposure AND depth of field this means very small amounts of light gets to the sensor. If you need high contrast images in this situation, something has to change. Either get more light, accept less depth of field, or have some image blur.

For a full listing of machine vision lenses, click here and use the filter to help in your selection.

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera selection. With a large portfolio of lenses, cables, NIC card and industrial computers, we can provide a full vision solution!

Related Blog posts

10 key things you need to know when selecting a machine vision lens

Information courteous of Wikipedia

For most cameras in the automated imaging marketplace, the sensor sizes are 1” and less. (1″ sensors have 16mm image circle/diameters)

For most cameras in the automated imaging marketplace, the sensor sizes are 1” and less. (1″ sensors have 16mm image circle/diameters)

the camera, the automated imaging industry has created several products to use these lenses. The solutions from Birger Engineering,

the camera, the automated imaging industry has created several products to use these lenses. The solutions from Birger Engineering,