Single sensor machine vision cameras use a mosaic filter placed on the sensor to create color images. This is also called a ‘Bayer’ filter, named after the person who invented it. However, color images from this filter lose resolution and color fidelity compared to ‘true’ color images. Spatial resolution is lost due to interpolation, while the Bayer filter pattern reduces true color representation, sensitivity and dynamic range. To overcome these issues, multi-sensor (3-CCD / 3-CMOS) machine vision cameras can be used.

Typically, machine vision 3-CCD cameras were high cost, until now with CMOS sensors becoming the leading image sensor technology. Now, machine vision 3-CMOS machine cameras provide major benefits over Bayer cameras and at more attractive entrance cost.

CMOS sensor technology has lowered the price of 3 image sensor cameras by 50% providing a better alternative to Bayer color cameras for many applications. JAI’s Apex Series 3-CMOS cameras are the game changer for demanding color applications.

Watch this video to learn more about 3-CCD/3-CMOS cameras

Machine Vision 3-CMOS cameras Vs Bayer cameras provide major benefits for color applications

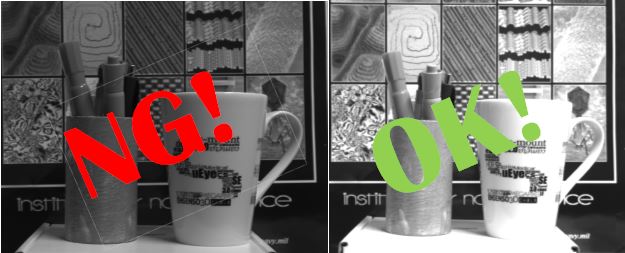

Better color precision – Accurate RGB values are obtained for each pixel so there is no interpolation/estimation of colors as found in Bayer cameras. This can be critical for paint/ink matching, printing inspection systems, digital pathology, or other applications where color values must be extremely accurate.

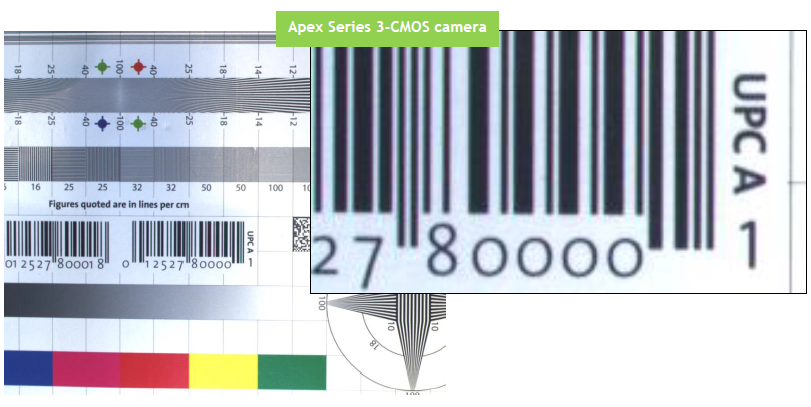

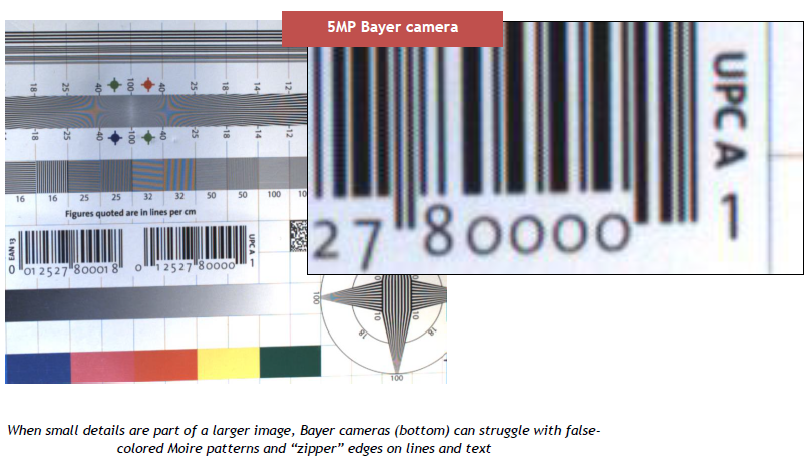

Better spatial resolution – The Bayer interpolation process also tends to blend edges and small details. While this can be pleasing to the eye, it can make spatial measurements or bar code reading imprecise or error prone, causing the use of more expensive high resolution Bayer cameras or requiring a second monochrome camera for imaging these details

Higher sensitivity – The prism glass in the AP-3200T-USB and associated cameras, has better light transmission properties than the polymer filters in a standard Bayer sensor. This enables more light to reach the pixels for better overall sensitivity and lower lighting requirements.

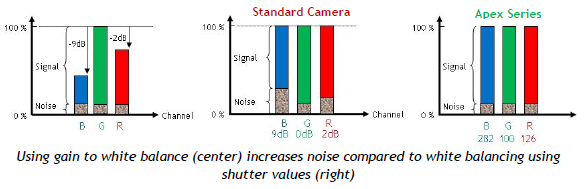

Lower noise, higher dynamic range – White balancing on a JAI prism camera can be done on individual channels with shutter adjustments instead of adding gain to the image. This results in lower noise and higher usable dynamic range.

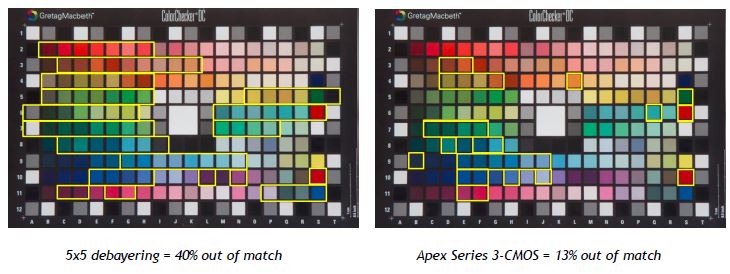

What about “improved” Bayer capabilities like 5×5 interpolation?

Several camera manufacturers claim vastly improved capabilities for color imaging, including 5×5 de-Bayering, color-anti-aliasing, denoising

and improved sharpness. But consider the following: 5×5 interpolation

means you are using an even larger area within the image to estimate each pixel’s color value. So while this can do a better job of “smoothing” color transitions to the eye, it can actually result in less-precise color values for image processing, especially where color variation is high.

More advanced color imaging features

More advanced color imaging features

JAI’s Apex 3-CMOS machine vision cameras provide additional advanced features aside from excellent color fidelity and highlighted as follows:

- Color Space conversion: Color data from the camera can be provided using built in conversions to several color spaces including sRGB, Adobe RGB, CIE XYZ and HSI. Custom RGB conversions can also be done using the cameras color matrix circuit.

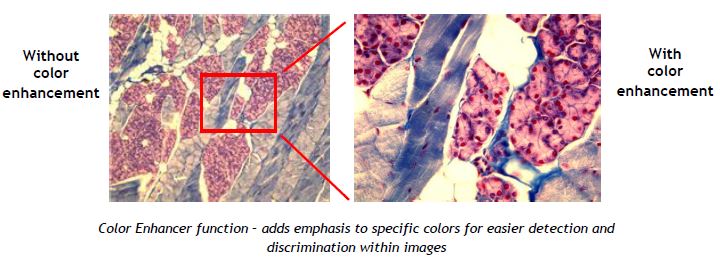

- Color Enhancer Function: Allows the 3-CMOS cameras to “boost” the intensity of 6 colors to help features stand out, such as the red color of blood vs surrounding tissue in a medical application. Additionally, degree’s of edge enhancement can be to increase the contrast of color boundaries.

- Color Binning: While most Bayer cameras do not offer this, due to the prism architecture of the 3-CMOS cameras, you can easily bin pixels by 1×2, 2×1 and 2×2 to increase sensitivity, reduce shot noise and / or increase the frame rate.

- Color temperature presets from 3200K, 5000K, 6500K and 7000K

All of these features, along with reduced costs for 3-CMOS color cameras, now make this a very attractive solution for demanding color applications! Applications in eye diagnostics, pathology, surgical imaging, meat/food inspection, print inspection and automotive color matching are a few that would highly benefit from the JAI Apex 3-CMOS camera series.

Need to proof 3-CMOS / 3-CCD prism based cameras will enhance your application? Let’s discuss sending you a demo camera!

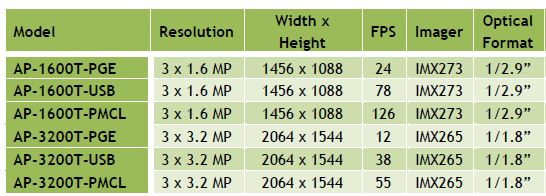

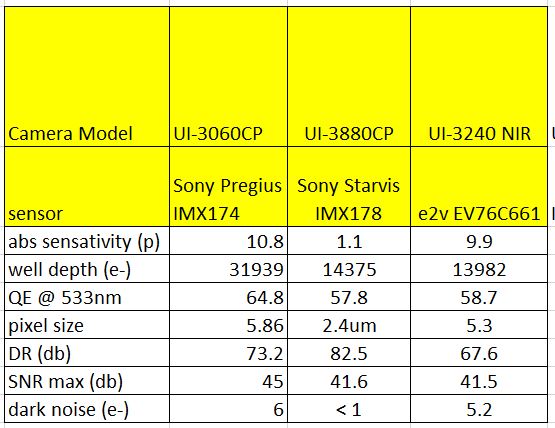

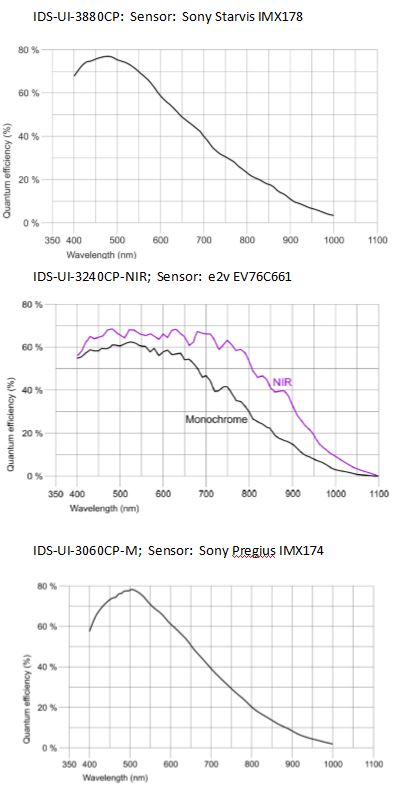

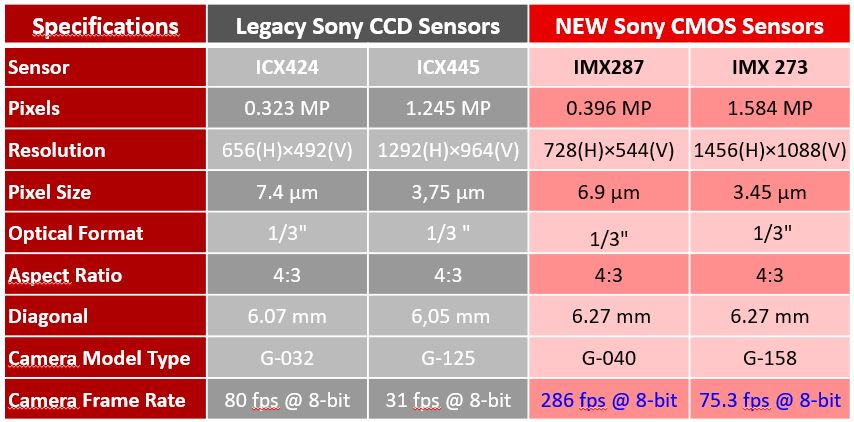

Currently there are 6 new CMOS models outlined below and full specifications can be found HERE.

1st Vision is the leading provider of industrial imaging components with over 100 years of combined imaging experience. Do not hesitate to contact us regarding the new prices of the 3-CMOS cameras!

Be sure to visit our related blogs on 3-CCD and Prism based cameras

How does a 3CCD camera improve color accuracy and spatial resolution versus standard Bayer color cameras?

White Paper – Learn about High Dynamic Range (HDR) Imaging techniques for Machine Vision

White Paper -How does prism technology help to achieve superior color image quality?