While a standard lens is adequate or even ideal for many machine vision applications, there is inherent distortion in a standard lens, often in the range of 1 – 2%. Telecentric lenses achieve distortion of 0.1% or less. They also provide constant magnification and no perspective error.

If you “just” need presence/absence detection, or counting discreet non-occluded objects, a conventional lens may be fine. But if you need highly accurate contactless measurement, telecentric lenses offer remarkable performance.

Courtesy Edmund Objects

Let’s take a brief look at what qualifies a lens as telecentric, and why you might want (or need) one. Subsequently we’ll summarize Edmund Optics SilverTLTM and CobaltTLTM lens series.

Telecentric Tutorial

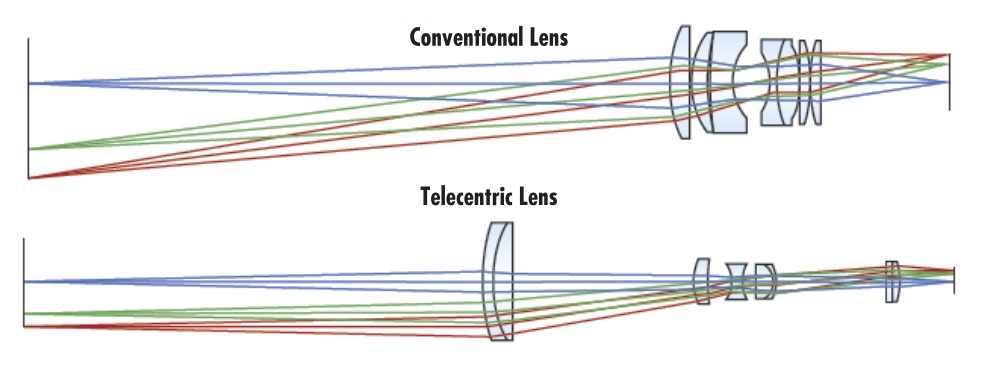

Telecentric lenses only accept incoming light rays that are parallel to the optical axis of the lens. It’s not that the oblique rays don’t reach the outer edge of the telecentric lens. Rather, it’s about the optical design of the lens in terms of what it passes on through the other lens elements and onto the sensor focal plane.

Hmm, but the telecentric lens must have a narrower Field of View (FoV) – and I have to pay a premium for that? Well yes – and yes. There are certain benefits.

Let’s get to an example. In the image immediately below, labeled “Setup”, we see a pair of cubes positioned with one forward of the other. This image was made with a conventional (entocentric) lens, whereby all three dimensions appear much the same as for human vision. It looks natural to us because that’s what we’re used to. And if we just wanted to count how many orange cubes are present, the lens used to make the setup image is probably good enough.

But suppose we want to measure the X and Y dimensions of the cubes, to see if they are within rigorous tolerance limits?

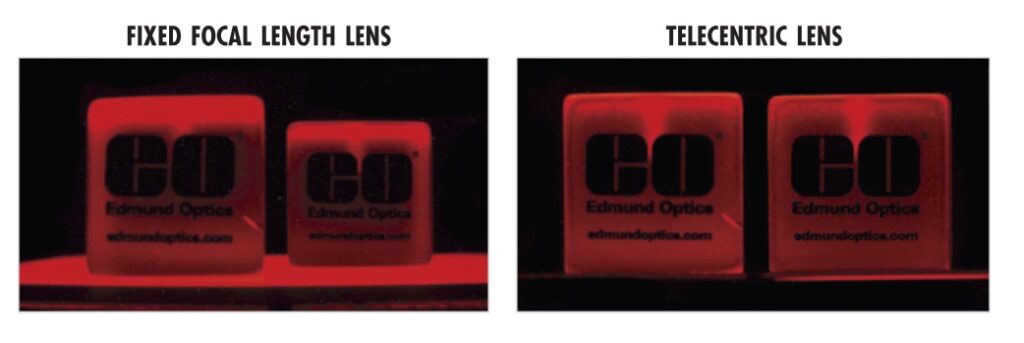

An object-space telecentric lens focuses the light without the perspective of distance. Below, the image on the left is the “straight on” view of the same cubes positioned as in “Setup” above, taken with a conventional lens. The forward cube appears larger, when in fact we know it to be exactly the same size.

The rightmost image below was made with a telecentric lens, which effectively collapses the Z dimension, while preserving X and Y. If measuring X and Y is your goal, without regard to Z, a telecentric lens may be what you need.

Depth of Field can be “pushed”

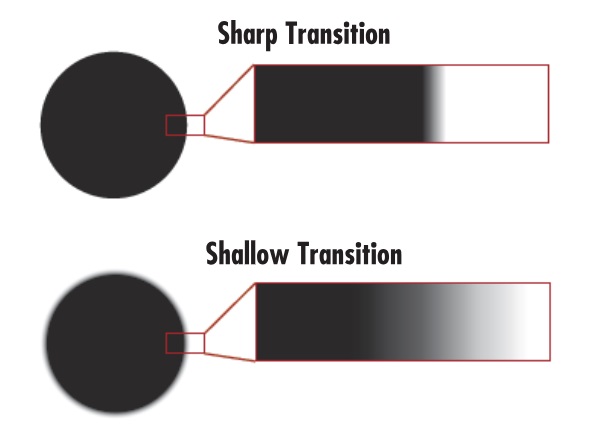

You are likely familiar with Depth of Field (DoF), the range in the Z dimension in which objects in the FoV are in focus. With a conventional lens, if an object moves out of focus, the induced blur is asymmetrical, due to parallax (aka. perspective error).

But with a telecentric lens, there is no parallax error, since the FoV is constant and non-angular. A benefit of this is that even if the target image is somewhat defocused with a telecentric lens, the image may still be perfectly usable.

In the two images below, the “sharp transition” edge is clearly optimal. But when measuring tolerances in a manufacturing environment, with mechanized conveyors, vibration, etc., target objects may not always be ideally positioned. So the “shallow transition” image from the object just out of focus is entirely acceptable to identify the center of mass for the circular object, since the transition is symmetrical at all positions.

Edmund Optics is widely recognized for their range of standard products – and their expertise in custom lens design when needed. The SilverTLTM and CobaltTLTM lens series each offer 10+ members, where all lenses are high-resolution and bi-telectric. Some additionally offer inline illumination options.

Noteworthy characteristics of both the SilverTL and CobaltTL series include:

- Aperture controls often not available in competitor products

- “Fast” ==> lower F# options than in many competitor products (so can work effectively with less light)

- Conform to narrowly specified engineering tolerances

- Pricing identical with or without in-line illumination via coax port

Edmund Optics SilverTLTM series

The SilverTL series pairs with C-mount sensors up to 7.5 MegaPixels, ideal with 2.8 µm pixel size. Magnification options range from 0.16X to 4X.

Edmund Optics CobaltTLTM series

For C-mount sensors up to 20 MegaPixels, and pixel size 2.2 µm, choose the CobaltTL series.

What type of lens is best for my application?

Machine vision is a broad field, with a lot of variables across wavelengths, application goals, sensor, software, and lens choices. If you are a seasoned veteran, you may know from experience exactly what you need. Or you may want to review our on-line knowledge base or online blogs. Easier yet – just phone us at 978-474-0044. You’ll speak with one of our sales engineers, who put customer success first. Customers with successful outcomes – who return to us project after project – is our goal.

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of lenses, cables, NIC cards and industrial computers, we can provide a full vision solution!