Sometimes just the Z-values are enough, no image needed at all. Some applications require pseudo-images generated from a point cloud – whether in monochrome or with color tones mapped to Z values. Yet other applications require – or benefit from – 3D digital point cloud data as well as color rendering. IDS Ensenso’s C Series provides stereo 3D imaging with precise metrics as well as true color rendering.

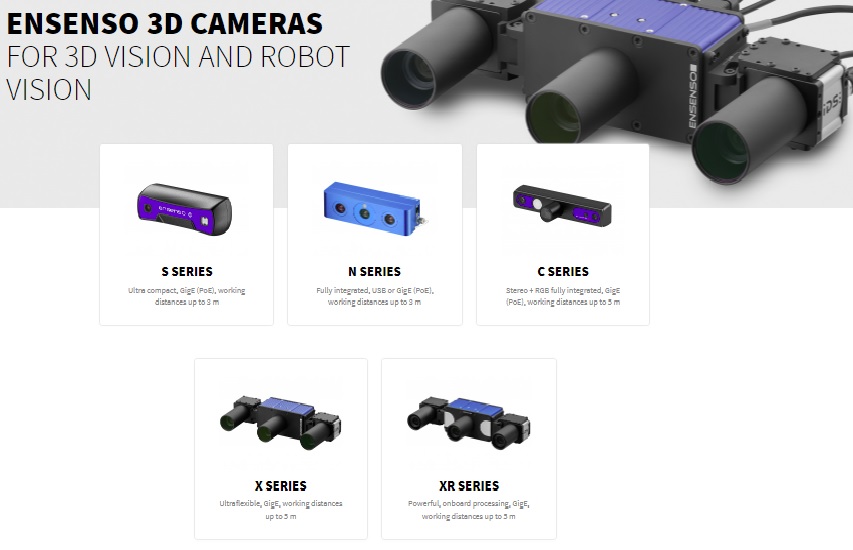

If you want an overview of 3D machine vision techniques, download our Tech Brief. It surveys laser triangulation, structured light, Time of Flight (ToF), and stereo vision. If you know you want stereo vision, you might like an overview of all IDS Ensenso 3D offerings.

But if you know you want stereo 3D accuracy to 0.1mm, with color rendering, let’s dive in to the IDS Ensenso C Series. If you prefer to speak with us instead of reading further, just call us at 978-474-0044, or request that we follow up via our contact form.

Key differentiator is “projected texture”

In the short video below, we see 3 scene pairs. For each pair, the leftmost images are the unenhanced 3D image. The rightmost images take advantage of the projected texture created by the LED projector and the RGB sensor, augmenting the 3D point cloud with color information. It can be a differentiator for certain applications.

Application areas

Let’s start with candidate application areas, from customer perspective, before pointing out specific features. In particular let’s look at application areas including:

- Detect and recognize

- Bin picking

- De-palletizing

- Test and measure

Detect and recognize

The ability to accurately detect moving objects to select, sort, verify, steer, or count can enhance (or create new) applications. Ensenso C’s high-luminance projector enables high pattern contrast for single-shot images. Video courtesy of IDS.

Bin picking

Regardless of a robot’s gripping sensitivity, speed, and range of motion, 3D imaging accuracy is central to success. Ensenso C’s integrated RGB sensor can make all the difference for color-dependent applications. Video courtesy of IDS.

De-palletize

De-palletizing might seem like a straightforward operation, but must detect object size, rotation and position even with different and densely stacked goods. Ensenso C supports all those requirements – even from a distance. Video courtesy of IDS.

Test and measure

Automated inspection and measurement of large-volume objects are key for many quality control applications. Precision to the millimeter range can be achieved with Ensenso C at working distances even to 5m. Video courtesy of IDS.

IDS Ensenso C Series

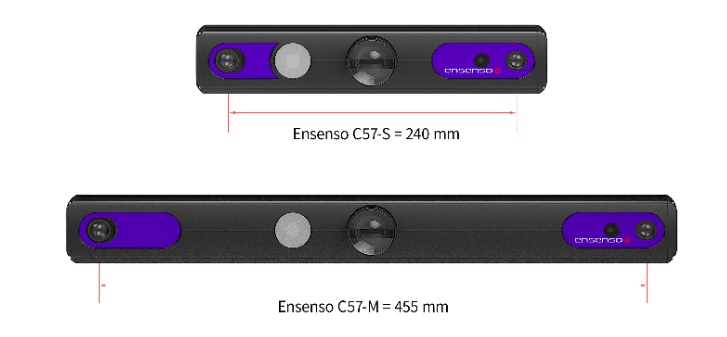

With two models to choose from, Ensenso C supports a range of working distances and focal distances – see specifications.

Both models utilize GigE Vision interface; both embed a 200W LED projector; both use C-mount lenses; both provide IP 65/67 protection. And both models are easy to configure with the Ensenso SDK: Windows or Linux; sample programs including source code; live composition of 3D point clouds from multiple viewing angles; robot eye-hand calibration; and more.

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of lenses, cables, NIC card and industrial computers, we can provide a full vision solution!