Opto Engineering is known and respected for high-performance lenses in machine vision, medical, and related fields. The new TCSE series are telecentric lenses designed for large sensor formats (4/3″, APS-C, APS-H). Each provides high resolution with low distortion.

Who needs a telecentric lens?

Before inviting you to some of the TCSE series features, let’s offer readers who aren’t already telecentric-savvy a brief motivation for this category of lens. If you are doing precise gauging applications – measuring via optics and software – your tolerances may require a telecentric lens. A telecentric lens eliminates perspective error. They have very low distortion. And, if paired with collimated light, they enhance edge definition.

For a comprehensive read, check out our blog Advantages of Telecentric Lenses in Machine Vision Applications. Not sure if you need a telecentric lens? Call us at 978-474-0044 – tell us a little about your application and we can guide you through any or all of lens, camera, lighting and other choices.

TCSE lenses are available for applications using light in either the visible spectrum or near-infrared (NIR) wavelengths. Currently there are 8 members in the TCSE product family.

Image circle diameter

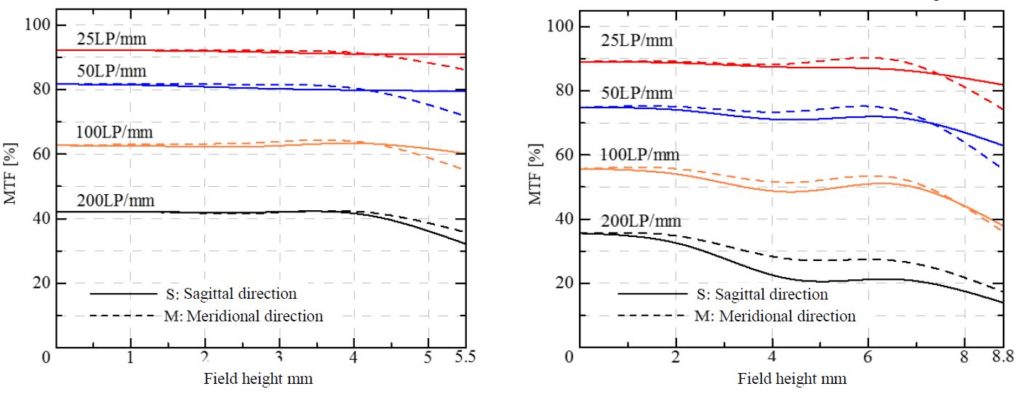

The TCSE Series offers image circle diameter options from 24 – 45mm.

Magnification

A key parameter in telecentric imaging is the level of magnification available. The 8 members of the TCSE Series offer magnification ranging from 0.36 through 2.75 times the original object size.

Working distance

The working distance (WD), from the front of the lens to the object being imaged, varies by lens model across the TCSE Series. The shortest WD offered is 160mm, spanning distances up to 240mm. These long working distances allow space for lighting and/or robotic arms.

Worth noting

While typically “plug and play” once mounted on your camera, it’s worth noting that the TCSE lenses offer back focal length adjustment, should one choose to fine tune.

Summary

Telecentric lenses are the core business for Opto Engineering, who have more than 20 years expertise in research, development, and production. 1stVision, North America’s largest stocking distributor, works to understand each customer’s application requirements, to help you select the ideal lens, camera, or other imaging component(s). Call us at 978-474-0044.

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of lenses, cables, NIC cards and industrial computers, we can provide a full vision solution!

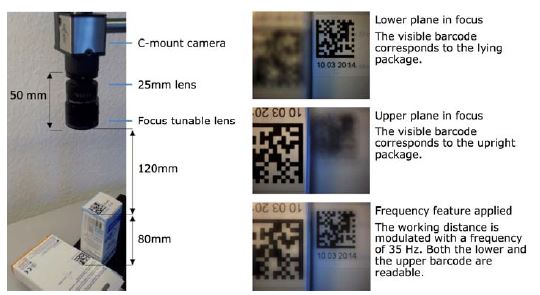

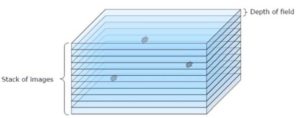

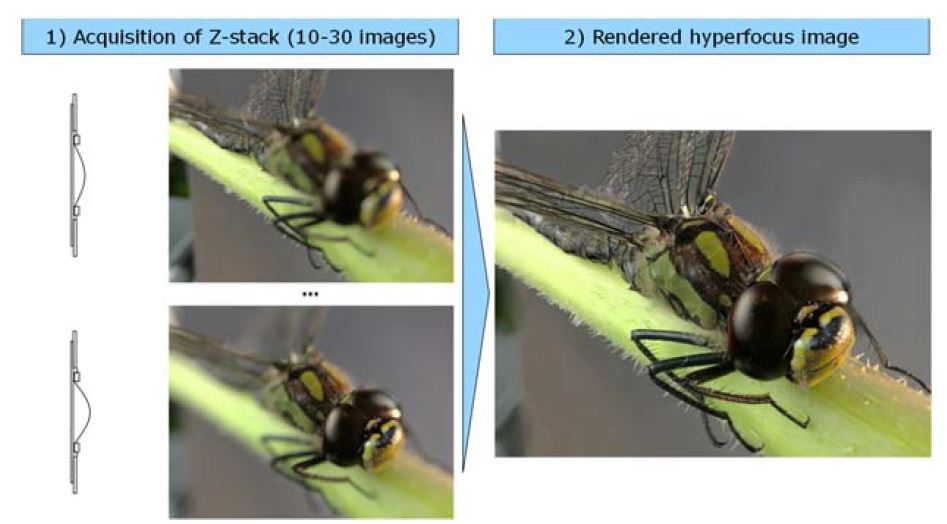

For this application, a liquid lens is used in conjunction with a telescentric lens taking images through different heights of the lens stack.

For this application, a liquid lens is used in conjunction with a telescentric lens taking images through different heights of the lens stack.