Pulsing (aka strobing) a machine vision LED light is a powerful technique that can be beneficial to machine vision systems in various ways.

Pulsing (aka strobing) a machine vision LED light is a powerful technique that can be beneficial to machine vision systems in various ways.

This blog post outlines 5 benefits you will receive from pulsing a LED light head. Gardasoft is an industry leader in strobe controllers capable of driving 3rd party LED light heads or custom LED banks for machine vision.

1 – Increase the LED light output

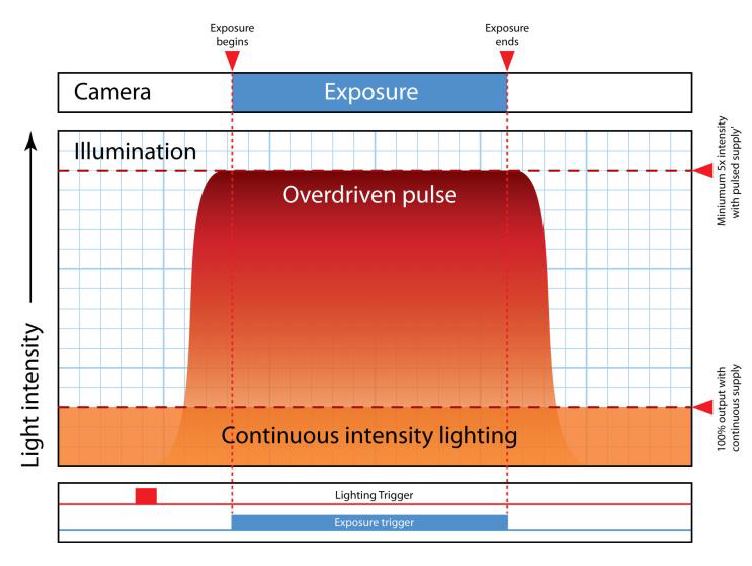

It is common to use pulsed light to “freeze” motion for high speed inspection. But, when the light is on only a short term in burst, its possible to increase the light output beyond the LED manufacturers specified maximum, using a technique called “Overdrive”. In many cases, the LED can be powered by 10X over the constant current power input in turn providing brighter pulses of light. When synchronized with the camera acquisition, a brighter scene is generated.

2 – Extend the life of the LED

As mentioned in the first benefit, strobing a LED light head only turns on the LED for short period of time. In many cases, the duty cycles are very low which extends the life of the LED and any degradation in turn, keeping the scene at a consistent brightness for years. (i.e. If the duty cycle is only 10%, the lifetime of the LED head will increase by 10%)

3 – Ambient Light control

Ambient light conditions frequently interfere with machine vision measurements and these issues can be solved by pulsing and over driving the system’s LEDs. For example, over driving the LED by 200% doubles the light intensity and enables the camera exposure to be halved, so reducing the effects of ambient light by a factor of 4. The end result is the cameras exposure is only utilizing light from the give LED source and NOT ambient light.

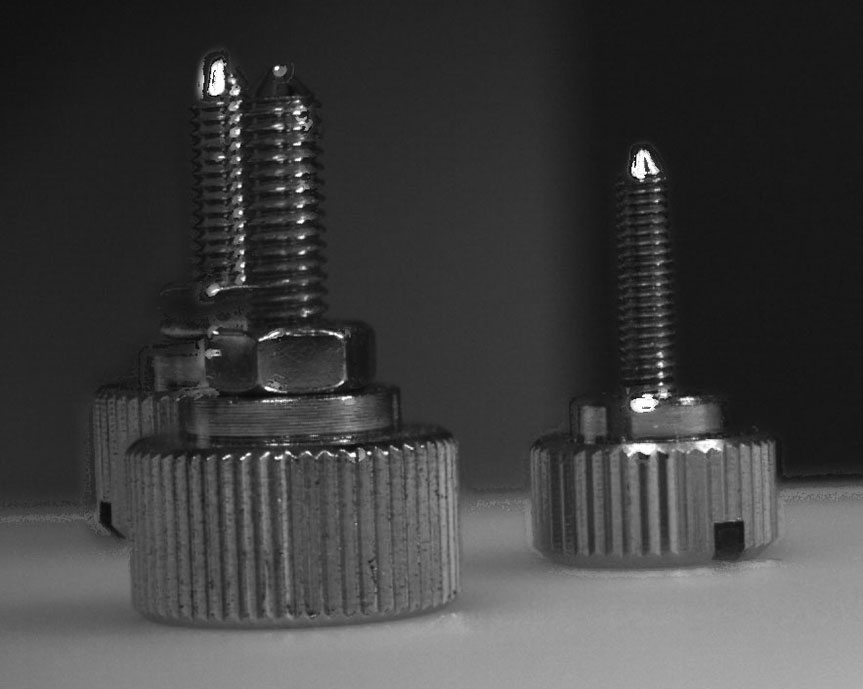

4 – High speed imaging and Increased depth of field

Motion blur in images from fast-moving objects can be eliminated with appropriate pulsing of the light. In some cases a defined camera exposure will be good enough to freeze motion (read our blog on calculating camera exposure), but may suffer in light intensity with constant illumination. “Over driving” a light can boost the output up to 10x its brightness rating in short pulses. Increased brightness could allow the whole system to be run faster because of the reduced exposure times. Higher light output may also allow the aperture to be reduced to give better depth of field.

Gardasoft controllers include our patented SafePower™ and SafeSense™ technology which prevents over driving from damaging the light.

5 -Multi-Lighting schemed & Computational Imaging

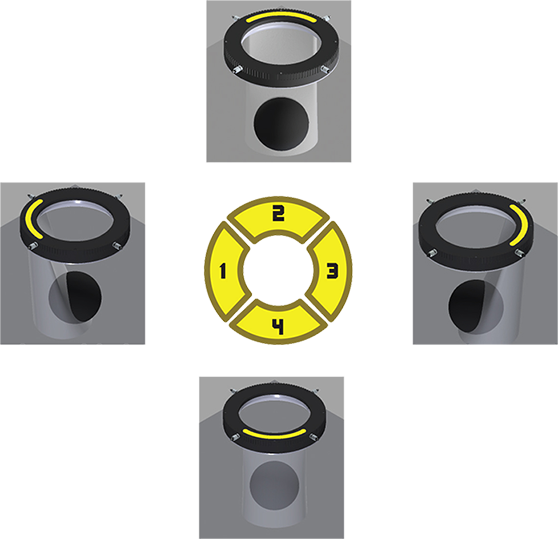

Lighting controllers can be used to reduce the number of camera stations. Several lights are set up at a single camera station and pulsed at different intensities and duration’s in a predefined sequence.

Each different lighting can highlight particular features in the image. Multiple measurements can be made at a single camera station instead of needing multiple stations and reduces, mechanical complexity saving money. For example, sequentially triggering 3 different types of lighting could allow a single camera to acquire specific images for bar code reading, surface defect inspection and a dimensional check in rapid succession.

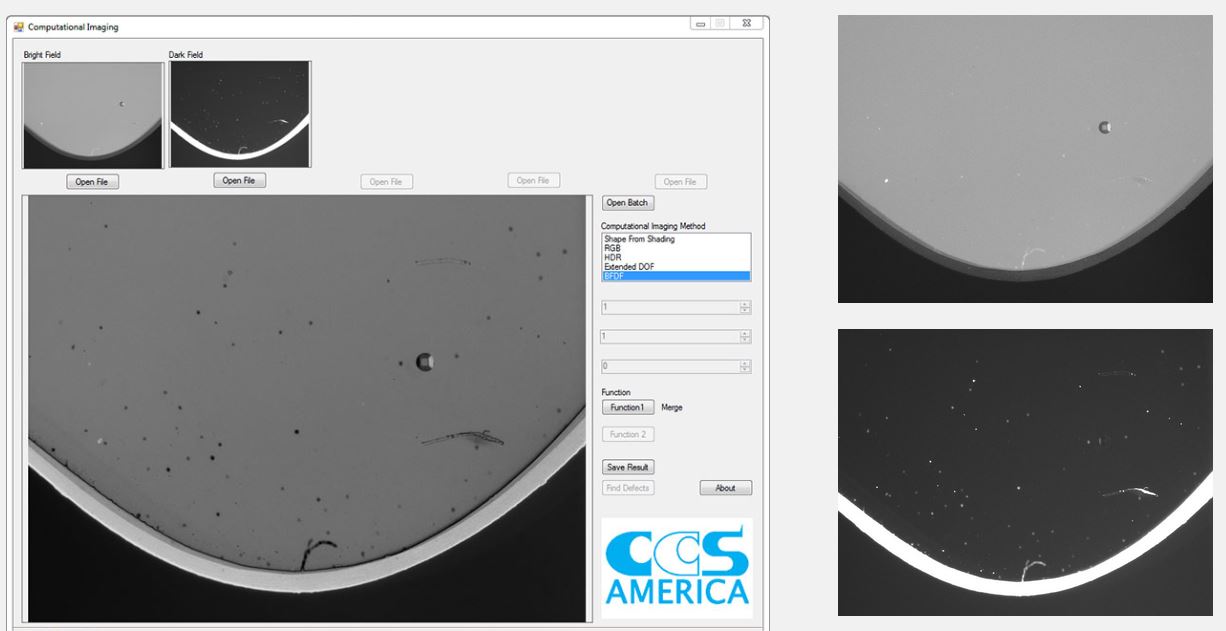

Pulsing can also be used for computational imaging, where a component is illuminated sequentially by 4 different lights from different directions. The resultant images would be combined to exclude the effect of random reflections from the component surface. Contact us and ask for the white paper on Computational imaging to learn more

Pulsed multiple lighting schemes can also benefit line scan imaging by using different illumination sources to capture alternate lines. Individual images for each illumination source are then easily extracted using image processing software.

In conclusion, strobe controllers can provide many benefits and save money in an overall setup more than the cost of a controller!

1st Vision has additional white papers on the following. Contact us an ask for any one of these informative white papers – Simply send an email and ask for 1 or all of the white papers.

1- Practical use of LED controllers

2 – Intelligent Lighting for Machine Vision Systems

3- LED Strobe lighting for ITS systems

4 – Liquid Lens technology and controllers for machine vision.

5 – Learn about computational imaging and how CCS Lighting can help

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera selection. With a large portfolio of lenses, cables, NIC card and industrial computers, we can provide a full vision solution!

Related Topics

White Paper – Key benefits in using LED lighting controllers for machine vision applications