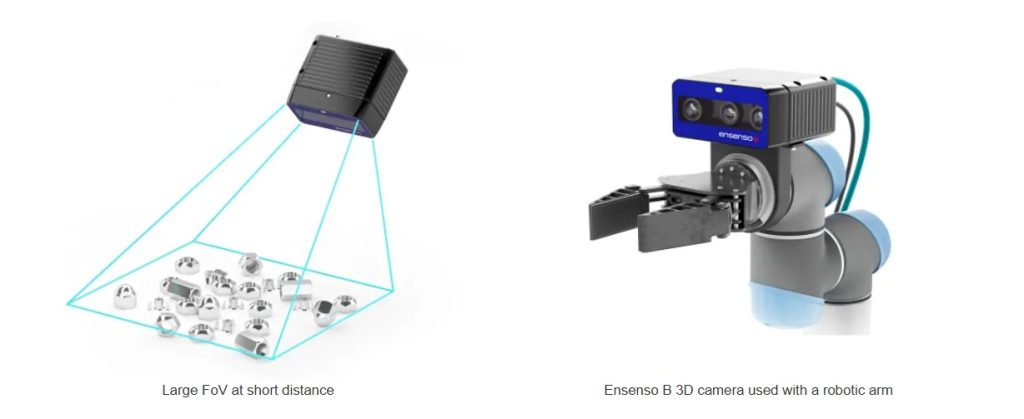

Previously we’ve written about Ensenso series members, like the B-Series for closeup, the C-Series for color, or the whole Ensenso family (B, C, N, S, X, and XR). Or you may have read 3D scanning overviews. 3D applications are myriad, from medicine, industrial, robotics, and more.

Whether you are new to applying imaging to logistics, or looking to upgrade current systems, 3D machine vision continues to drive innovation and opportunities.

In this piece we focus on logistics. Consider:

| Conveyor object inspection and classification | depth data enables detection, sorting, and volume measurement |

| Bin-picking and parts handling | accurate depth perception helps robots identify and locate items in bulk containers |

| (De-) Palletizing automation | 3D vision supports robot arms in stacking and unstacking pallets |

| Loading / Unloading trucks | 3D object localization improves automation |

Application areas

- Detect and recognize

- Bin picking

- De-palletizing

Detect and recognize

The ability to accurately detect moving objects to select, sort, verify, steer, or count can enhance (or create new) applications. Ensenso C’s high-luminance projector enables high pattern contrast for single-shot images. Video courtesy of IDS Imaging.

Bin picking

Regardless of a robot’s gripping sensitivity, speed, and range of motion, 3D imaging accuracy is central to success. Ensenso C’s integrated RGB sensor can make all the difference for color-dependent applications. Video courtesy of IDS Imaging.

De-palletize

De-palletizing might seem like a straightforward operation, but must detect object size, rotation and position even with different and densely stacked goods. Ensenso supports all those requirements – even from a distance. Video courtesy of IDS Imaging.

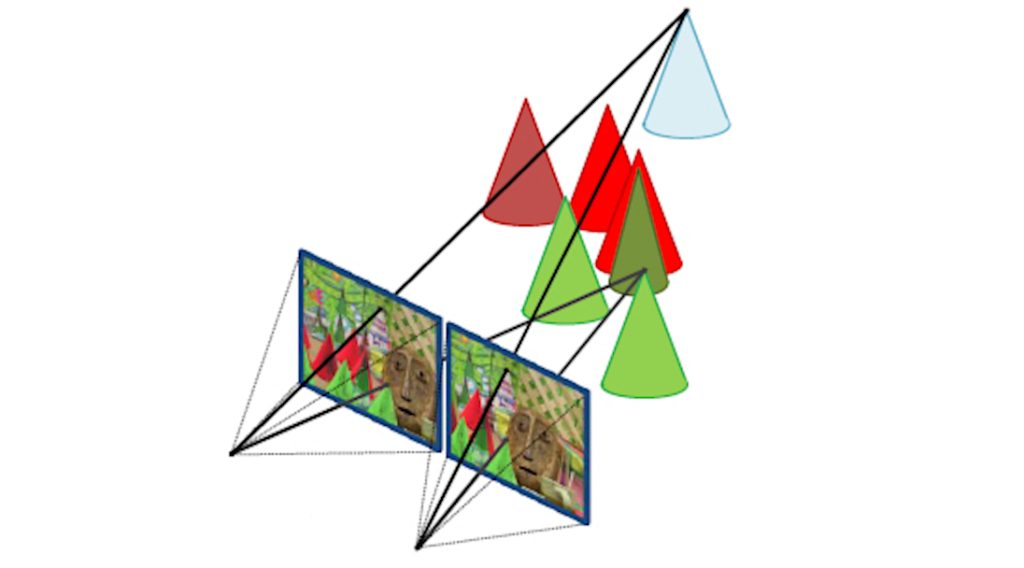

How does stereo imaging work?

Two-eyed humans and other animals, as well as two-camera stereo systems, use triangulation to achieve depth perception. If a given point on an object’s surface is offset more from one sensor than another, the collection of all such measurements can be used to create a point cloud model of the 3D scene.

You’ve got options – multiple stereo imaging setups

IDS Imaging Ensenso 3D cameras and camera systems are built for industrial 3D imaging with a GigE interface for ease of setup. There are monochrome and color options, as well as hybrid/blended systems. Short-distance capabilities to a few millimeters. Long-distance systems with WD to 5 meters. Modular pre-housed systems. And ruggedized systems for harsh environments.

Want some help with your logistics systems planning?

Call us at 978-474-0044. Our sales engineers come from diverse machine vision backgrounds, and we stake our reputation on helping clients select the best components and systems.

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of cameras, lenses, cables, NIC cards and industrial computers, we can provide a full vision solution!

About you: We want to hear from you! We’ve built our brand on our know-how and like to educate the marketplace on imaging technology topics… What would you like to hear about?… Drop a line to info@1stvision.com with what topics you’d like to know more about.