A GigE frame grabber? What’s that about? Those who work with Camera Link or CoaXPress cameras need frame grabbers for frame transfer, but GigE?

Frame grabbers use an industry standard PCI Express expansion bus to deliver high speed access to host memory for images. They get the image from the camera, via the cabling and frame grabber, at high speed, into the host, for processing.

But I already do GigE Vision without this so why might I want one?

- Avoid corrupted images arising from lost packets

- Reduce CPU load

- Synchronize images from multiple cameras

- Perform color conversion in the frame grabber rather than the host

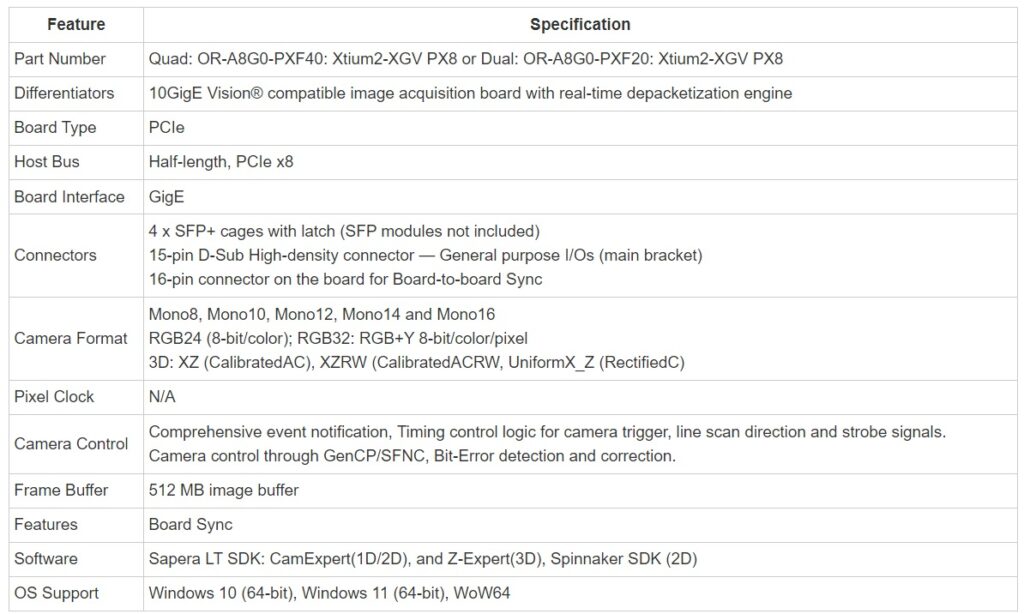

The full name of DALSA’s GigE frame grabber series is Xtium2-XGV PX8. It’s available in both dual and quad configurations, as shown in the image below.

More than an adapter card

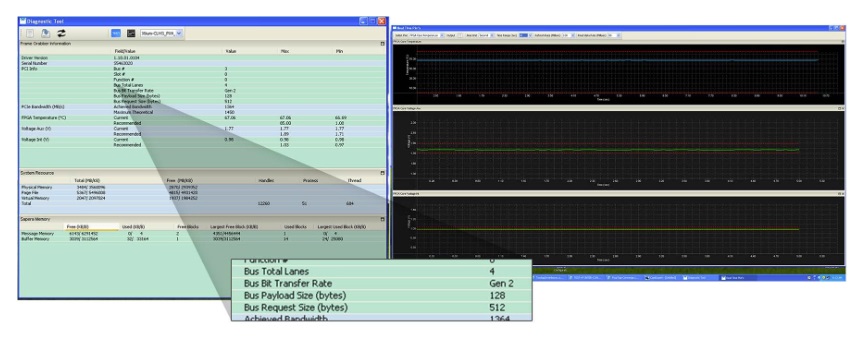

The Xtium2-XGV PX8 image acquisition cards use a real-time depacketization engine to create a ready-to-use image from the GigE Vision image packets. With packet resend logic built in, image transfer reliability is enhanced. And host CPU load is reduced. So already we see two benefits.

But wait there’s more!

Supporting up to 32 cameras, these boards aggregate input bandwidth of 4 GByte/s and up to 6.8 GBytes/sec output bandwidth to the host memory. They can also perform on-board format conversions like Bayer to RGB, Bi-color to RGB, etc.

So it’s really an “Aggregator-conditioner-converter-pre-processor”

Exactly! Which is why we call it a frame grabber for short.

Psst! Wanna see some specs?

Free software

Acquisition and control software libraries are included at no charge. Teledyne DALSA’s Sapera LT SDK. Hardware independent by design, Sapera LT offers a rich development ecosystem for machine vision OEMs and system integrators.

So do you need one or want one?

So an Xtium2-XGV PX8 frame grabber is an aggregator-conditioner-converter-pre-processor. It accepts multi-port GigE Vision inputs, improves reliability, optionally does format conversions, and reduces load on the host PC. If your prototype system is struggling without such a frame grabber, maybe this is the missing link. Or maybe you want to get it right on the first try. Either way, tell us more about your application, and we’ll help you decide if this – or some other approach – can help. We love partnering with our customers to create effective machine vision solutions. Call us at 978-474-0044!

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of lenses, cables, NIC cards and industrial computers, we can provide a full vision solution!